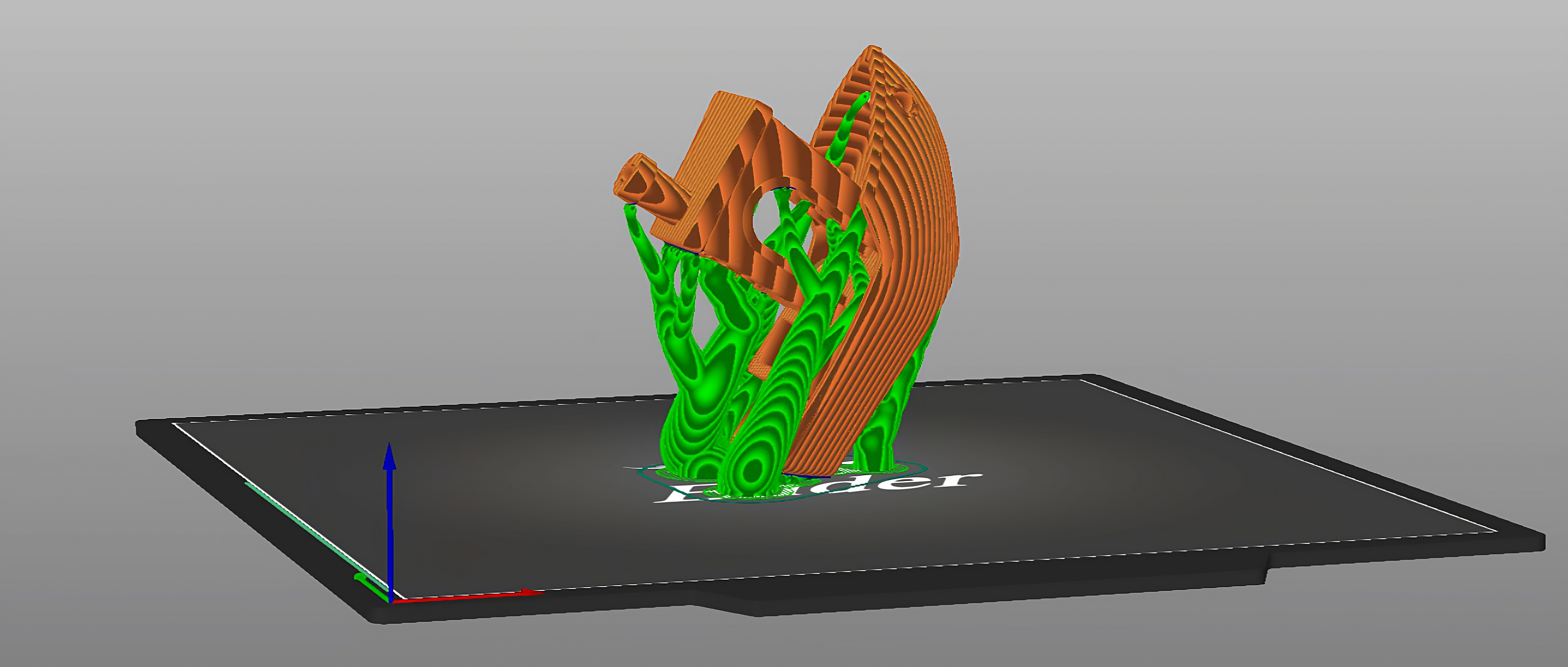

Celestrius is an AI model that uses a simple nozzle camera instead of a LiDAR to tackle a slew of notorious 1st-layer issues: under/over extrusion, bed adhesion problem, wrong z-offset, you name it.

One of the innovations by Bambu Lab's X1 is a LiDAR that watches the 1st-layer for potential print issues.

On one hand, the Obico team is excited to see a new, innovative solution promised to address the issues that cause endless headaches to even the most-experienced 3D printing enthusiasts.

On the other hand, we don't believe LiDAR is an optimal choice for this task. The reasons are:

-

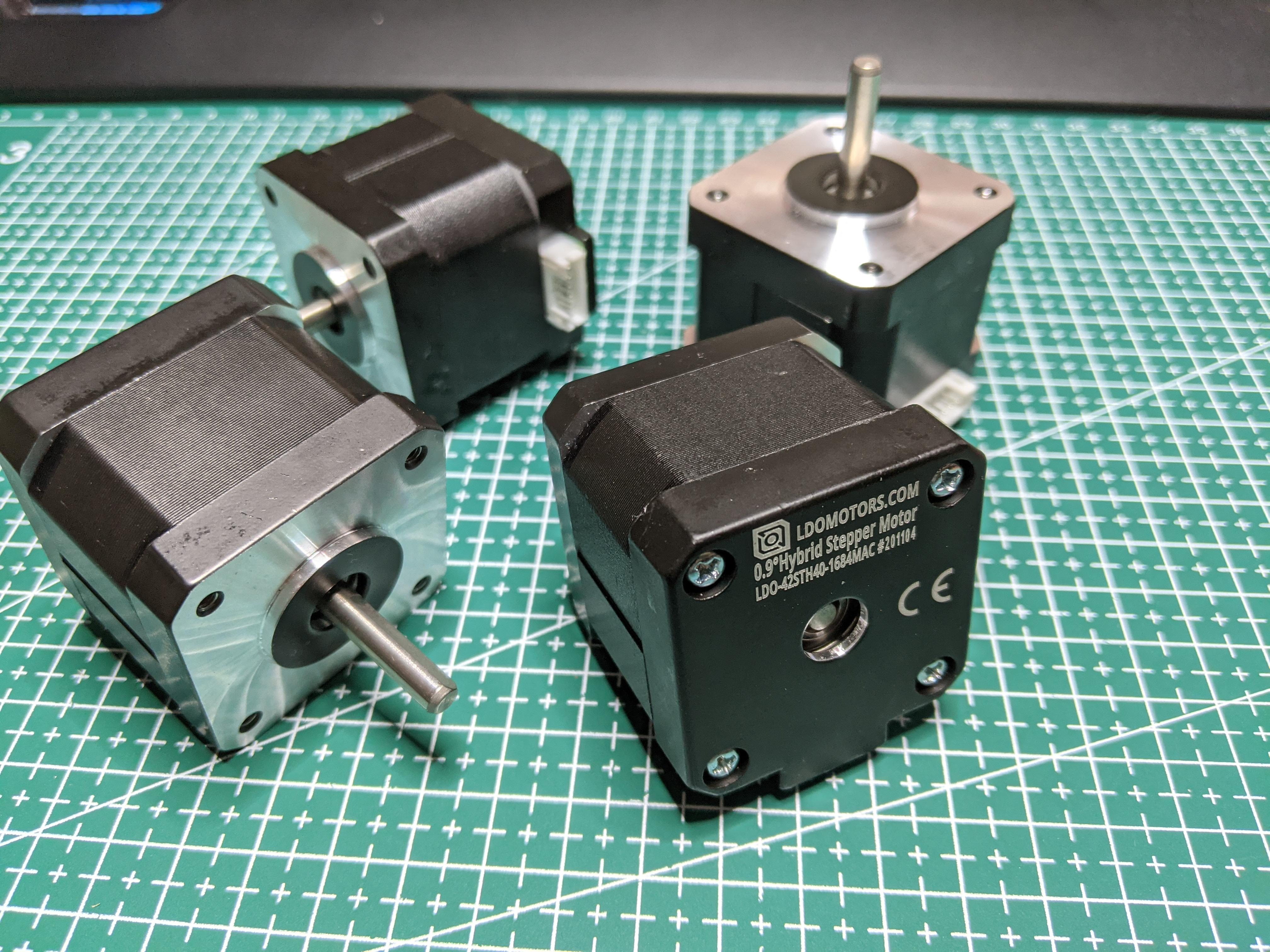

LiDARs are proprietary, expensive, and hard to source. This is a walled-garden solution that isn't aligned with the maker ethos deeply rooted in the 3D printing community.

-

AI technologies centered around cameras are advancing at a much faster pace than those for LiDARs.

-

LiDARs are for robots only. Cameras are for both robots and humans. Who doesn't enjoy watching a jaw-dropping video like this?

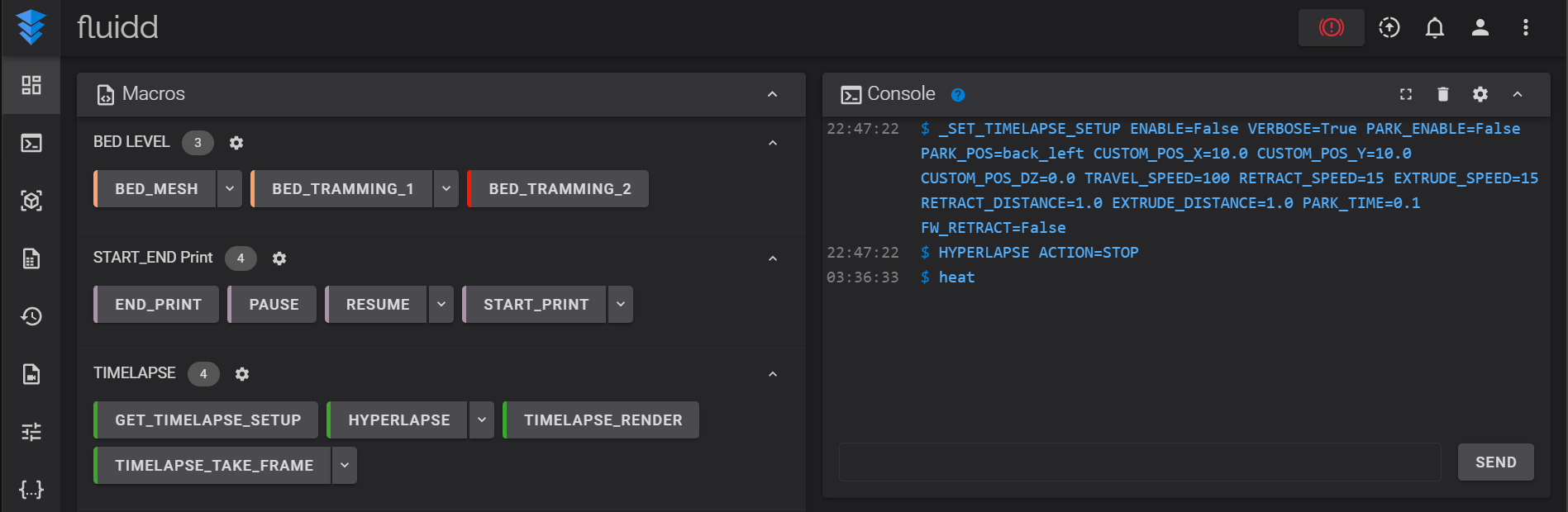

That's why the Obico team started project Celestrius - an AI model that will be a lot smarter than our current one simply thanks to the nitty-gritty detail a nozzle camera can reveal.

Well, this is the hope at least. In reality, we are not there yet because this project is damn hard! After tens of failed experiments, hundreds of print hours to collect data, and thousands of cups of coffee (Ok, may not be that much coffee. But you get the point), we now need your participation to push this project over the finish line.

And this is why we have now opened a limited pilot for project Celestrius.