Obico First Layer AI (codename: Celestrius) Alpha Deep Dive

Obico First Layer AI (codename: Celestrius) has rolled out to hundreds of alpha testers so far. Now let's hear what the alpha testers have to say:

What is Obico First Layer AI?

The First Layer AI system utilizes the up-close view of the nozzle cam to evaluate the first layer of your print. It tells you if your first layer didn't go down properly and hence may cause issues for the rest of the print.

Currently in the alpha testing phase Obico First Layer AI scans for these issues:

- Over and under-extrusion

- Adhesion issues

- Nozzle Blobbing

- Warping

- Bubbling

As we are continously adding more to this list as we get more data from our alpha testers!

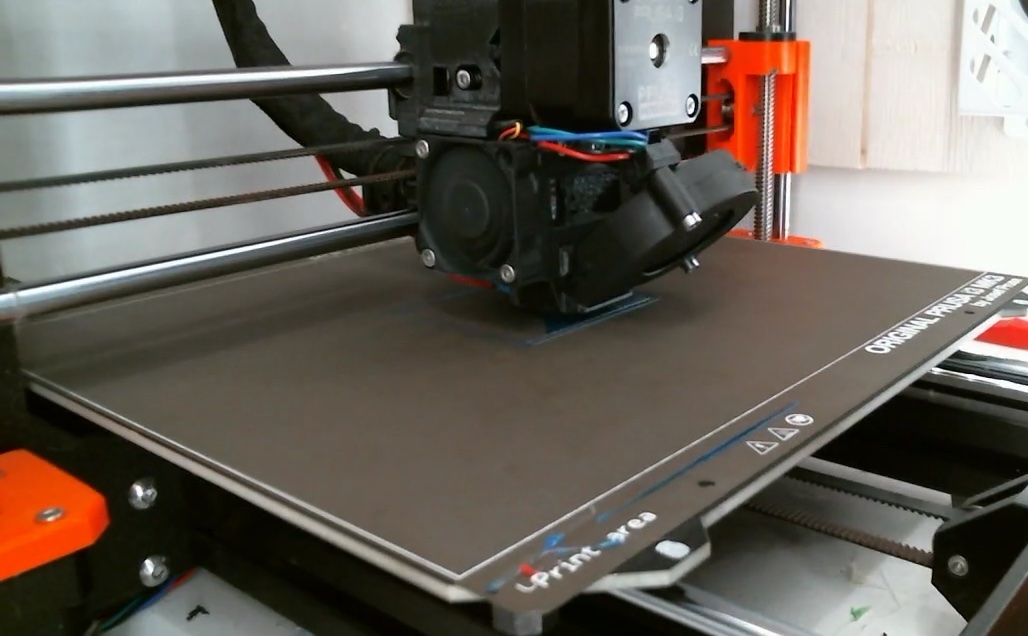

How is it different from Obico's failure detection?

The most important difference is First Layer AI works on nozzle cameras, whereas Obico failure detection AI works on regular webcams.

The up-close view of the nozzle camera allows the AI to see clearly the tiny defects that would be completely missed by Obico failure detection AI in a zoomed-out view.

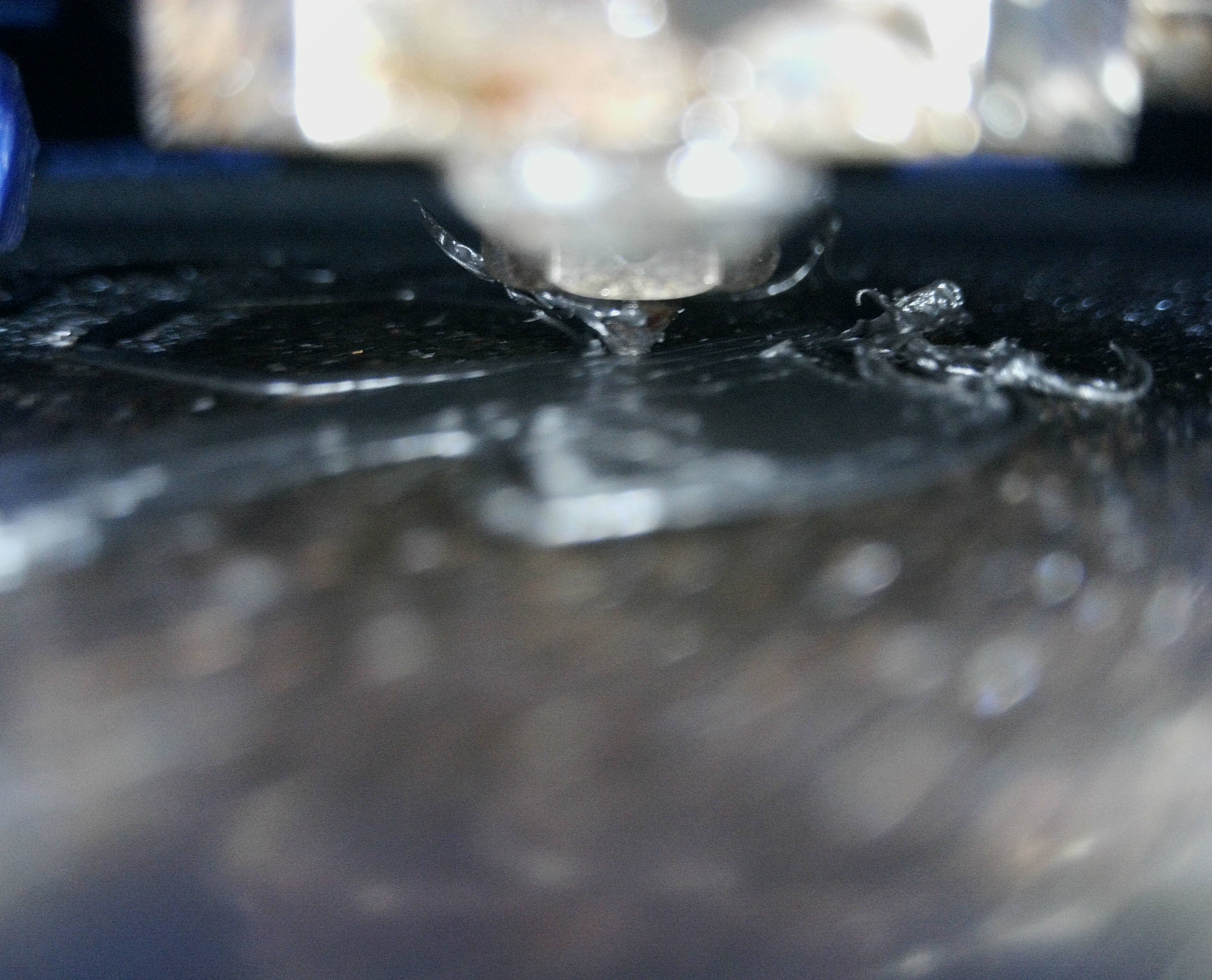

For instance, this printer below is having troubles with its first layer. The picture on the left is from its regular webcam. The defect can hardly be seen. No wonder Obico's failure detection AI missed it.

The picture on the right the up-close view of the nozzle camera. The defect is so clear that our First Layer AI caught it without even trying! As you can see later in this article, the First Layer AI can even catch defects that are a lot more subtle than this one.

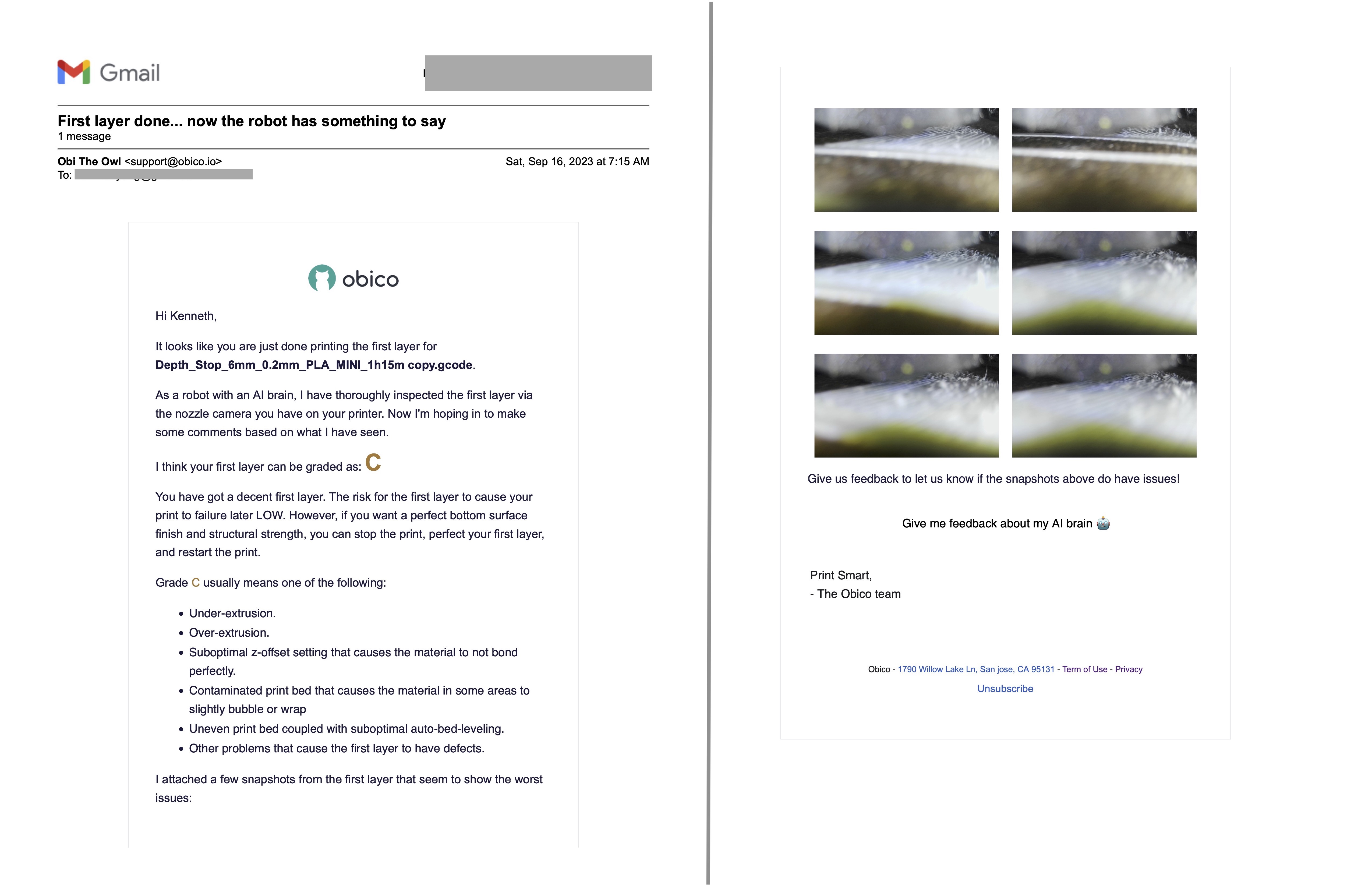

How does it exactly works for alpha testers?

Easy! Alpha testers set up their nozzle cameras and tell Obico where to find their nozzle cameras (the snapshot URL). After that, everything happens automatically.

Immediately after an alpha tester's printer has laid down the first layer, Obico First Layer AI leaps into action.

- It inspects the nozzle camera snapshots taken during the first layer printing;

- It then does its AI-magic to grade the first layer into one of A, B, C, D, or F - yees just like an elementary school teacher;

- sends a report to the alpha tester to let him/her know if:

- "Nothing to worry about. Your print will be fine!", or

- "Oh no! The first layer really doesn't look good. You'd better cancel the print now!".

Pixel-detection vs Box-detection

We made technological break-through in Obico First Layer AI: a more precise, pixel-based AI algorithm.

In 2019, we pioneered the first AI-based failure detection: The Spaghetti Detective. What we adopted at that time was a "box detection" mechanism. This mechanism splits a webcam picture into 16x16-pixel boxes and makes detection based on these boxes.

Although this method has since been adopted by other AI failure detection solutions such as Print Nanny or QuinlyVision, it suffers from a fundamental shortcoming: the 16x16-pixel boxes are too coarse to detect fine details.

In Obico First Layer AI, we led the industry again by figuring out how to run the AI algorithm at the pixel level. The advantage is obvious: the First Layer AI can "see" tiny problems that otherwise would be missed by box-detection.

Ok enough about the talking. Let's dive into a few examples.

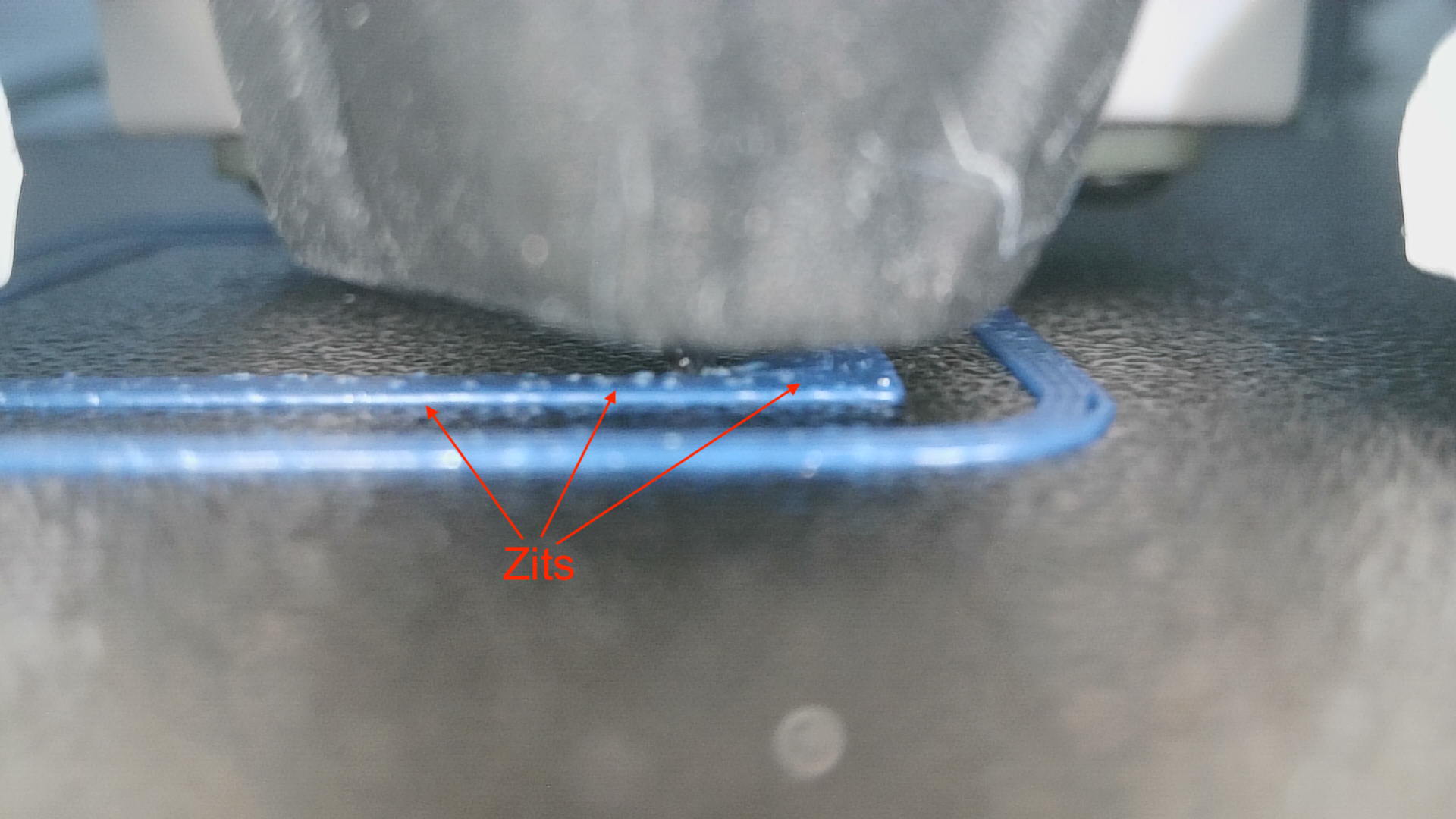

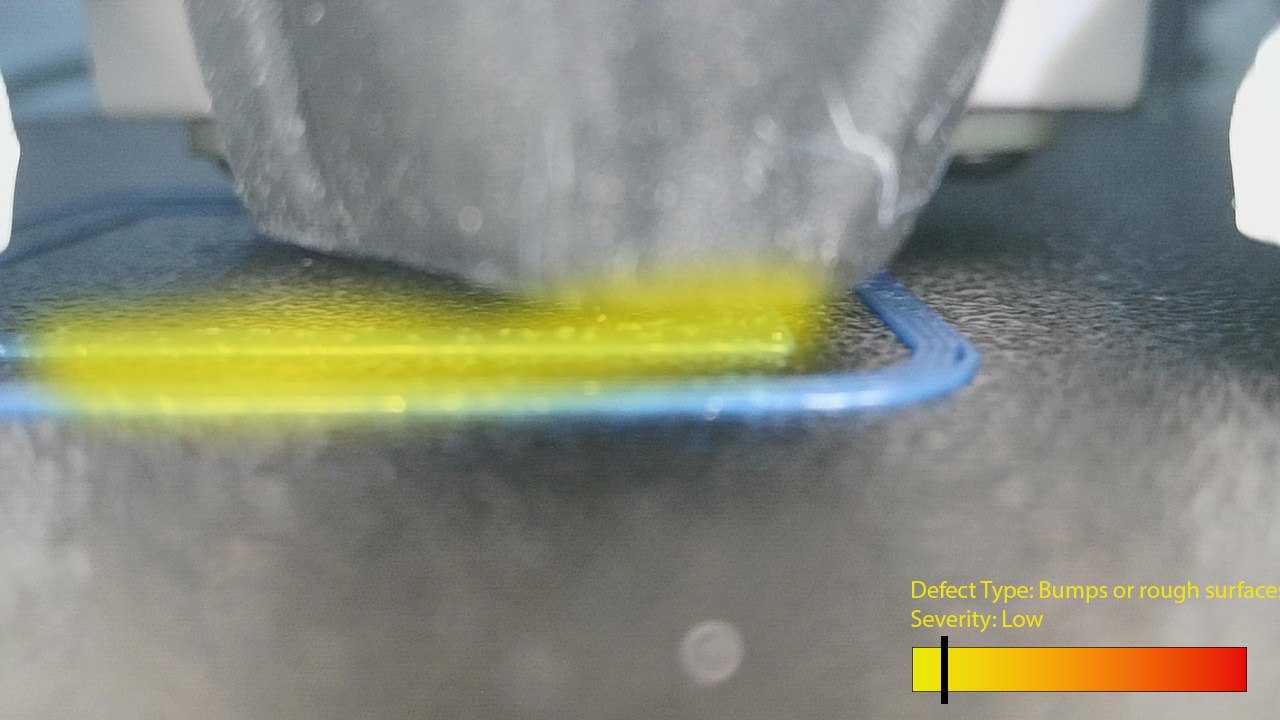

Example 1. Tiny zits and bumps

There are tiny zits and bumps for this print. Obico First Layer AI correctly highlighted the pixels that contains the issue, and assessed the severity as "Low".

(Top: Original image. Bottom: Inspected by Obico First Layer AI.)

Oh by the way, the regular webcam view of the same print is the picture below. You are probably not surprised that nothing showed up in the regular failure detection. 😝

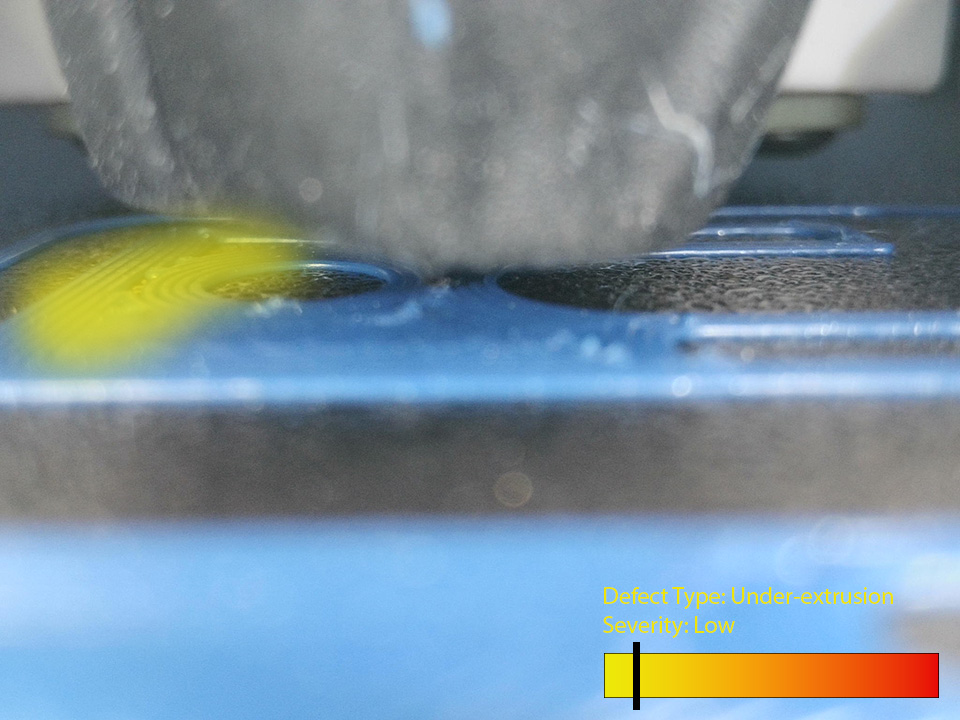

Example 2. Under-extrusion

This under-extrusion would have been overlooked by people with a ton of 3D printing experience. But it was caught with easy by the Obico First Layer AI's pixel-based algorithm.

(Top: Original image. Bottom: Inspected by Obico First Layer AI.)

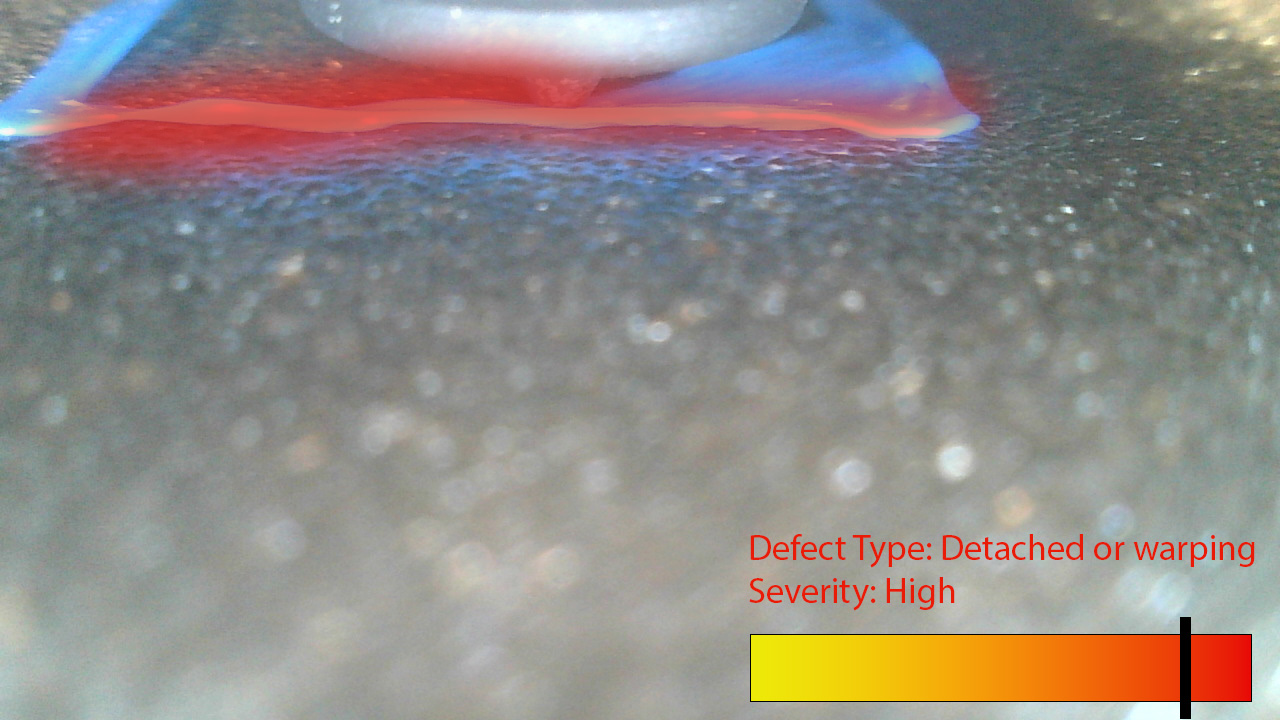

Example 3. Detached or warping

In this example, the part barely started to warp and get detached from the bed. It immediately got identified by the Obico First Layer AI and assessed the severity as "High".

(Top: Original image. Bottom: Inspected by Obico First Layer AI.)

Example 4. Z-offset issue

(Top: Original image. Bottom: Inspected by Obico First Layer AI.)

Example 5. Blobs!

And of course, we shouldn't conclude this deep dive without an example of dreaded blobs! The good news? The Obico First Layer AI can detect blobs with 100% accuracy! Finally blobs damaging quipments will become a history!

(Top: Original image. Bottom: Inspected by Obico First Layer AI.)

Conclusion

With a specialized lidar, Bambu Lab's X1C came up with an innovative solution (by the way their AI seems to still be box-detection, not pixel-detection) as an answer to all kinds of first-layer issues that have long plauged the 3D printing community. Obico First Layer AI is our answer using a commodity device that all makers can source and implement themselves.

Based on the alpha testing data we have had so far, we have enough confidence that our AI algorithm is more accurate and reliable than Bambu Lab's. Of course we respect Bambu Lab for what they have achieved so far, and we know they are working very hard to improve their algorithm too. But hey we are trying pretty hard too! And we believe this is how we motivate each other to continously push the envolope for the 3D printing community!