Ender 3 3D Printer Comparison Guide

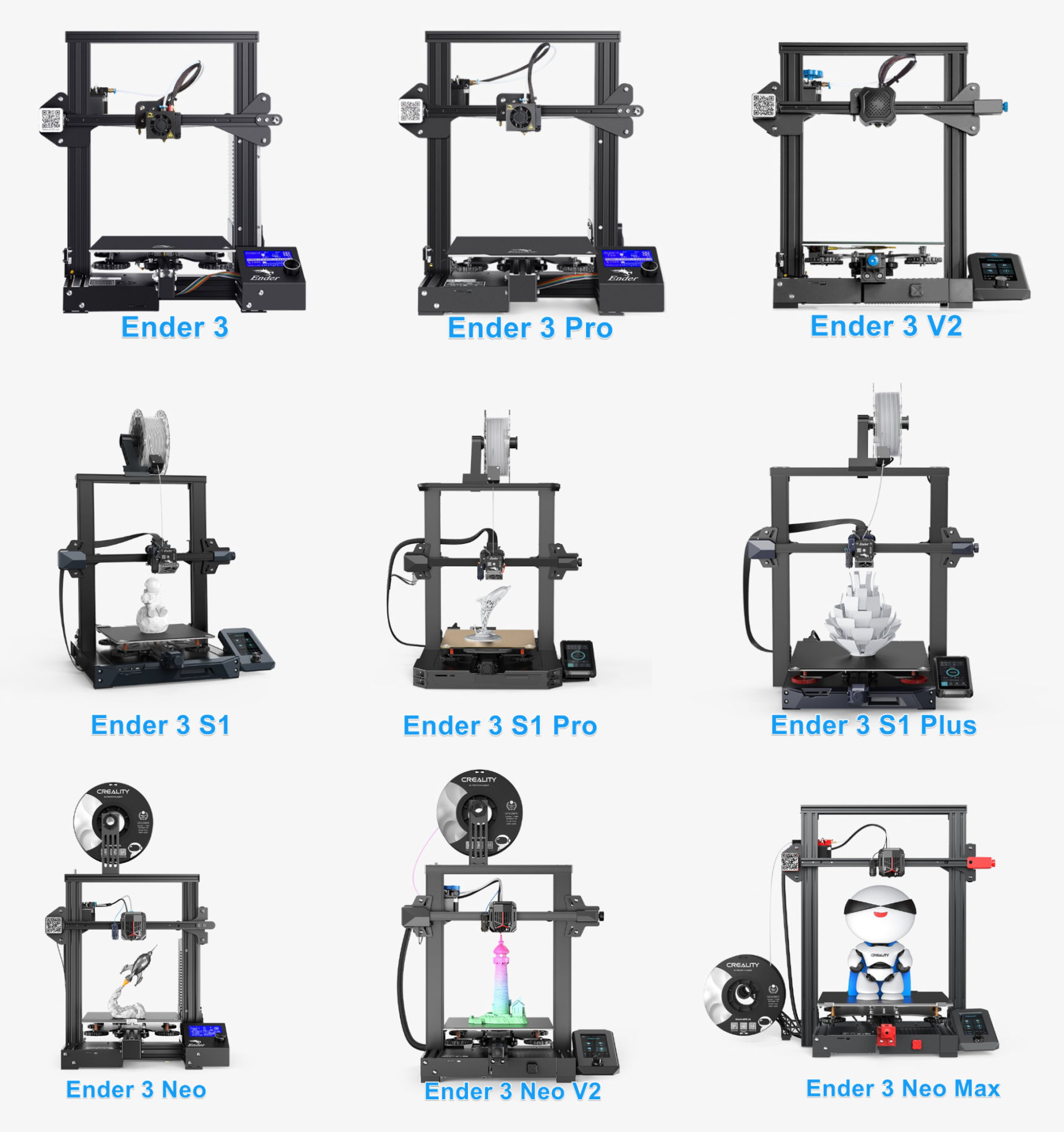

Creality released its first-ever Ender 3 model in March of 2018. It was an instant success and became widely popular due to its budget pricing and decent build quality. Ever since the company's released improved models, which retain the original Ender 3's form factor but come with a slew of impressive features at a relatively low cost.

But, cumulatively, there are now 10 Ender 3 models in three different series. Some of the printers have similar features to the previous generations, while others are entirely upgraded with a slight price bump. This becomes confusing for many buyers, and you might buy an Ender 3 that's not ideal for your 3D printing needs.

In this article, we'll clear out this confusion and understand the similarities and differences between all ten printers. It will help you to make an informed decision and get an Ender 3 that is better suited for you.

Let's get started and end the Ender confusion once and for all.

Original Ender 3 series

The original Ender 3 series is one of the first Ender 3 3D printers that laid the foundation for subsequent generations. Creality released four 3D printers in this series: The Ender 3, Ender 3 Pro, Ender 3 V2, and Ender 3 Max, particularly in that order.

The Ender 3 is a basic, budget 3D printer aimed at hobbyists and beginners. It set the tone for many entry-level 3D printers, and its design quickly became popular amongst several 3D printer users.

The Ender 3 Pro carries over the same design, albeit with some minor improvements in features. In contrast, the Ender 3 V2 got a clean look and a great set of features which you can still see in the latest generation of Ender 3's.

Lastly, the Ender 3 Max comes with a massive build volume and is a 'maxed' out version of the smaller Ender 3s. There are hardly any differences in features, and the printer is positioned as an alternative to Creality's CR-10 series.

Let's take a look at the various features of the Ender 3 series and understand the differences between these printers.

Comparison Sheet

| Features | Ender 3 | Ender 3 Pro | Ender 3 V2 | Ender 3 Max |

|---|---|---|---|---|

| Build Volume | 220 x 220 x 250 mm | 220 x 220 x 250 mm | 220 x 220 x 250 mm | 300 x 300 x 340 mm |

| Release Year | 2018 | 2018 | 2020 | 2020 |

| Machine Dimensions | 440 x 410 x 465 mm | 440 x 410 x 465 mm | 475 x 470 x 620 mm | 513 x 563 x 590 mm |

| Extruder drive | Bowden | Bowden | Bowden | Bowden (Metal) |

| Max hot end Temperature | 255 ºC | 255 ºC | 260 ºC | 260 ºC |

| Max print bed temperature | 110 ºC | 110 ºC | 110 ºC | 110 ºC |

| Print surface | Textured BuildTak style | "C-MAG" magnetic plate | Carborundum glass | Carborundum glass |

| Bed Leveling | Manual | Manual | Manual | Manual |

| User Interface | Rotary Knob LCD | Rotary Knob LCD |

| Color HD screen with Rotary knob | Rotary Knob LCD

| | Dual Z-axis | No | No | No | No | | Belt Tensioners | No | No | Yes | No | | Filament sensor | No | No | No | Yes | | Price | $189 | $236.00 | $249.00 | $329 |

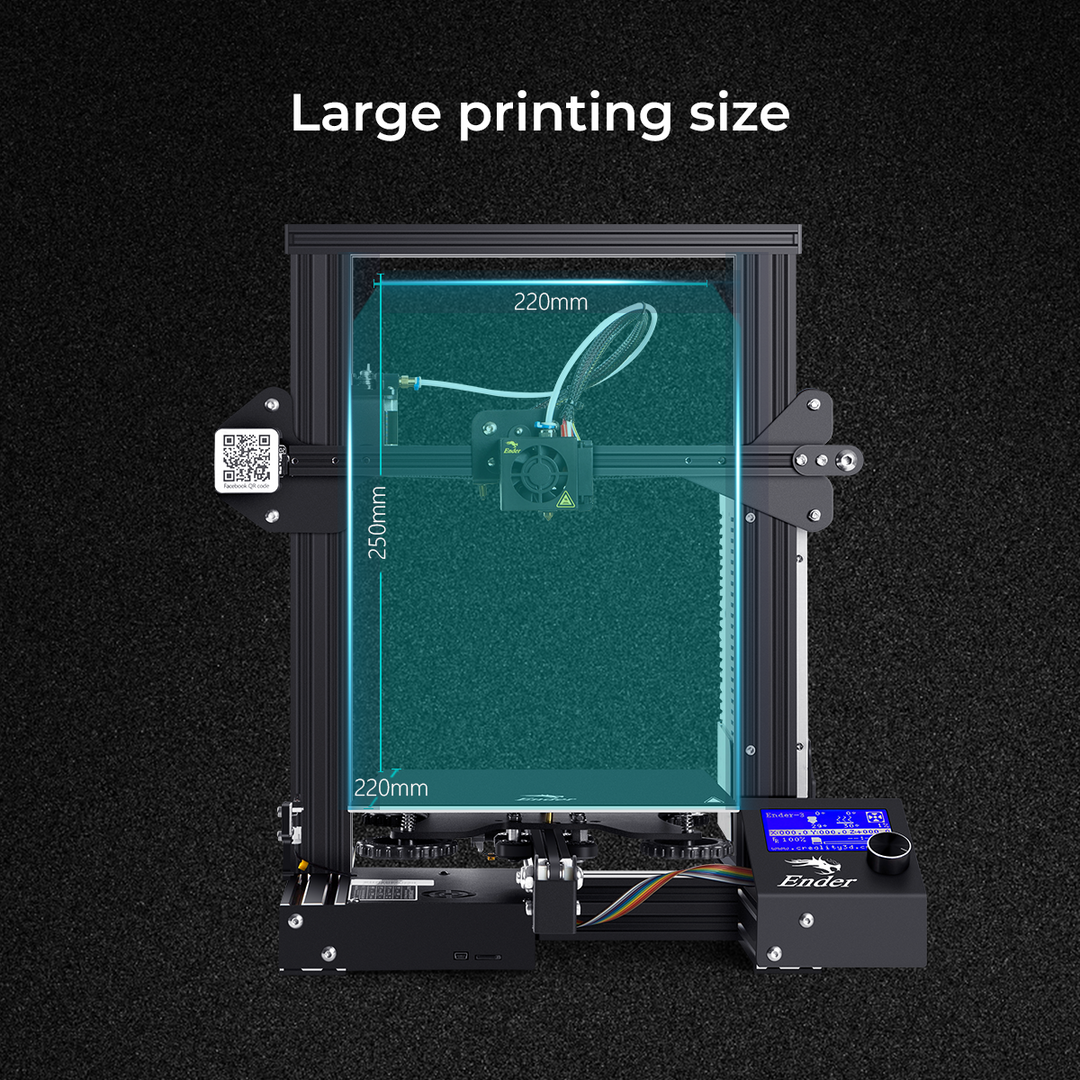

Build Volume

Ender 3 build volume Source: Creality

The build volume remains unchanged in Ender 3, Pro, and the V2 3D printers. Each printer features a 220 x 220 x 250 mm print volume. On the other hand, the Ender 3 Max receives a massive build volume of 300 x 300 x 340 mm, the largest amongst all the Ender 3 3D printers.

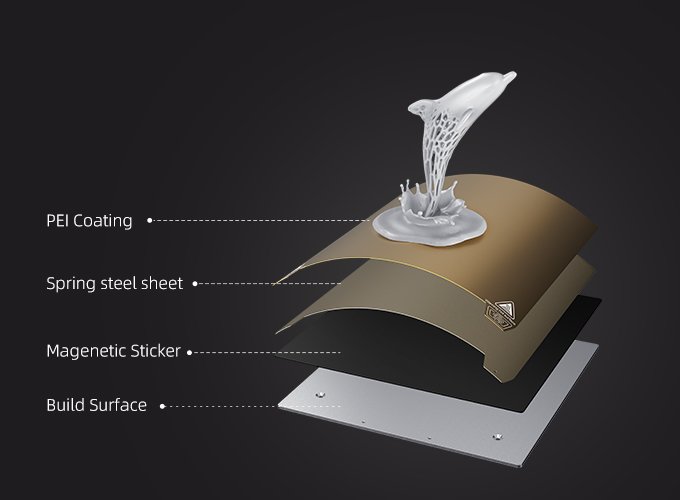

Print bed

The original Ender 3 printer got two different build surfaces. Some printers feature a removable BuildTak style print bed, while others have a non-removable print surface. Yet, both print beds perform well in the print adhesion and removal areas.

The Ender 3 Pro is upgraded in this area and features a removable, flexible magnetic print bed. This facilitates easy removal of prints while still delivering excellent print adhesion.

For the Ender 3 V2 and the Ender 3 Max, Creality decided to use flat, carborundum glass print beds as the default printing surface. These glass beds are superb for distributing heat evenly but are heavier than magnetic print beds. But, you get a glossy and shining first layer, as opposed to the coarse layer with other print bed types.

User Interface

Ender 3, Pro, and the Max share a rather old TFT screen with a control knob for navigation. While it's functional, the small screen limits the functions the printer can display and feels a bit dated in terms of design.

The Ender 3 V2 features a tall, vertical screen display with an improved user interface. It uses a rotary knob for navigation, and you can visualize the various functions quickly in a neat integrated manner.

Other features

All the Ender 3 in this series feature a strikingly similar design, albeit with minor differences. The Ender 3 Pro, V2, and Max have a bottom-facing cooling fan for the motherboard, unlike the top-facing in the Ender 3. This design prevents any filament bits from falling into the controller unit.

You also receive a Meanwell Power supply in all three printers, except for the Ender 3. It's a high-quality power unit and reduces the chances of breakdowns and failures.

The Ender 3 V2 is the sole printer in the series to get a redesigned fan shroud, XY axis belt tensioners, and a toolbox. Additionally, there's a filament knob on the extruder, which helps to control the filament manually. These are all ideas from the community, which Creality has included in their 3D printers.

The presence of a 32-bit motherboard on the Ender 3 delivers a silent 3D printing experience. You also get this on the Ender 3 Max with its 2208 TMC stepper drivers, but it misses out on a 32-bit motherboard.

At last, the Ender 3 Max gets dual cooling fans on both sides of the nozzle, helping it deliver better cooling performance. And there's a filament run-out sensor to notify you and stop the print in case the filament breaks, or you run out of it.

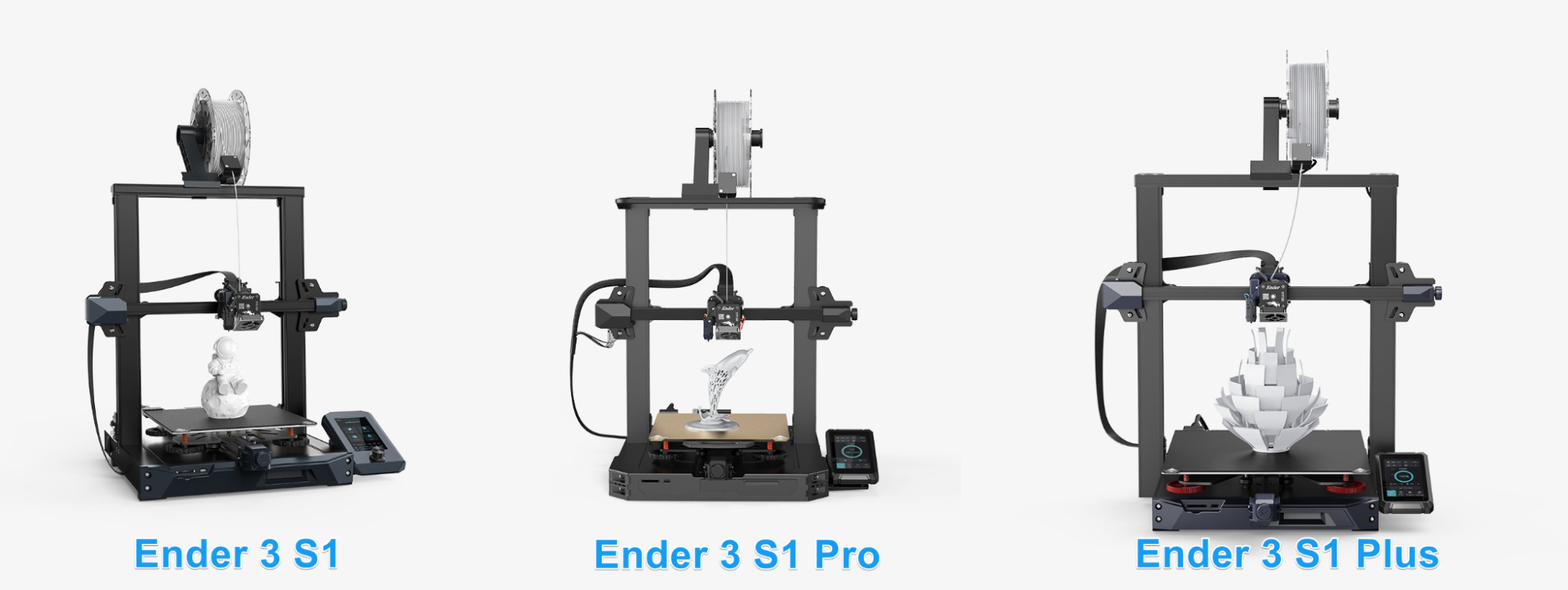

Ender 3 S1 Series

Creality released the Ender 3 S1 series as the next generation of 3D printers in the Ender 3 lineup. The Ender 3 S1 was launched around the end of 2021, with the Pro and Plus versions released in the consequent months.

The S1 3D printers are a complete refresh in design, features, user interface, and printing experience. These match the latest 3D printing standards and target a broad audience, including professionals and industrial applications. Therefore, the printers come with a slightly increased cost, and the base Ender 3 S1 is almost $400.

Yet, the Ender 3 S1 series is the best in its category and delivers a rich 3D printing experience. These printers would be ideal for intermediate users looking for a feature-rich 3D printer at a relatively affordable cost.

Comparison Sheet

| Features | Ender 3 S1 | Ender 3 S1 Pro | Ender 3 S1 Plus |

|---|---|---|---|

| Build Volume | 220 x 220 x 270 mm | 220 x 220 x 270 mm | 300 x 300 x 300 mm |

| Release Year | 2022 | 2022 | 2022 |

| Machine Dimensions | 487 x 453 x 622 mm | 490 x 455 x 625 mm | 557 x 535 x 655 mm |

| Extruder drive | Sprite Direct Drive PTFE | Sprite direct drive all-metal | Sprite Direct Drive PTFE |

| Max hot end Temperature | 260 ºC | 300 ºC | 260 ºC |

| Max print bed temperature | 100 ºC | 110 ºC | 100 ºC |

| Print surface | PC spring steel magnetic plate | PEI spring steel magnetic plate | PC spring steel magnetic plate |

| Bed Leveling | CR-Touch auto-leveling | CR-Touch auto-leveling | CR-Touch auto-leveling |

| User Interface | Color HD screen with Rotary knob | Touchscreen | Touchscreen |

| Dual Z-axis | Yes | Yes | Yes |

| Belt Tensioners | Yes | Yes | Yes |

| Filament sensor | Yes | Yes | Yes |

| Price | $399.00 | $479.00 | $529.00 |

Build Volume

Similar to the previous generation, the baseline Ender 3 S1 and the Ender 3 S1 Pro feature a 220 x 220 mm print bed. But, there's a slight increase in the print height of 20 mm, and now you receive a total Z-axis height of 270 mm with these printers. The Ender 3 S1 Plus is the big brother in the series, featuring a giant build volume of 300 x 300 x 300 mm.

Extruder-Hot End

Creality has introduced its proprietary Sprite extruders with the Ender 3 S1 printers. It's a direct drive extruder-hot end assembly installed in all three printers. But, only the Ender 3 S1 Pro features an all-metal hot end with a maximum temperature of 300 °C. Otherwise, the Ender 3 S1 and the Plus receive a PTFE-lined hot end with a top limit of 260 °C.

This extruder-hot end assembly is a substantial improvement and offers broad material compatibility and better printing performance than the original Ender 3 3D printers. The Ender 3 S1 Pro will be ideal if you want to print with high-temperature filaments.

Print Bed

Print beds on the Ender 3 S1 printers are excellent for print adhesion and removal. The Ender 3 S1 and the Plus feature a PC spring steel printing surface that magnetically attaches to the print bed. On the Ender 3 Pro, you get a PEI-coated, magnetic spring steel print bed.

Both the print beds offer excellent printing performance, and prints stick well to both surfaces without needing adhesives or glue sticks. The flexible nature of the print bed also facilitates easy print removal without any additional tools. The PEI print surface is superb for a wide variety of materials and complements the printer's high-temperature printing capabilities well.

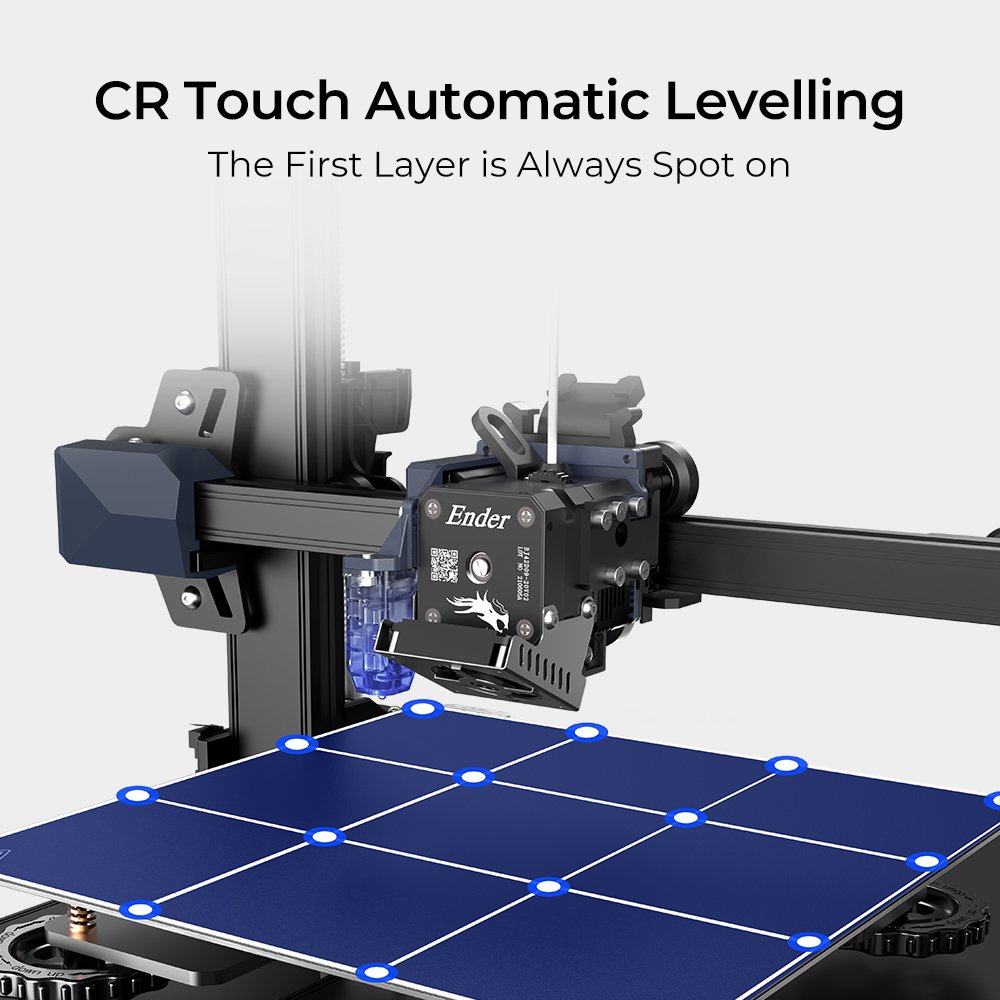

Auto-Bed Leveling

The Ender 3 S1 features a fantastic auto-bed leveling feature that was missing from the previous generation of Ender 3s. Auto-bed leveling removes the hassle of manually leveling the print bed and makes it easy for you to get a smooth and even first layer. This functionality also reduces the chances of print failures due to poor print adhesion.

Creality utilizes its leveling probe - CR Touch and maps around 16 points on the print bed to compensate for uneven printing areas. It's a neat feature to have and certainly saves a lot of printing time and effort.

Dual Z-axis Design

Creality introduced dual, synchronized Z-axes on all the Ender 3 S1 3D printers. While it's not a necessary feature for the small print area of the Ender 3 S1 and the S1 Pro, the dual lead screws help with better stability in the Ender 3 S1 Plus. For some reason, Creality skipped this feature on the Ender 3 Max, which would have benefited from double lead screws.

Nonetheless, it's a great addition to the S1 series and helps the printers maintain print quality while printing at high speeds. The prints have reduced ringing and ghosting, and the printing arm stays level without noticeable sag.

User Interface

To add to the premium look of the Ender 3 S1 series, Creality has upgraded the printers with full-color screens and an intuitive user interface. The screen on the S1 does not get touch support, and you instead navigate it using the rotary knob. It's reminiscent of the previous Ender 3's and balances the old tech with new screens.

On the other hand, you receive full-color touch screens on the Ender 3 S1 Pro and the S1 Plus. These screens offer quick navigation and give the printer a premium feel.

Language Support

Somehow Creality decided to skip on the language support for the baseline Ender 3 S1, and the printer supports solely Chinese and English languages. The Ender 3 S1 and the S1 Plus support nine languages, making us wonder why they decided to skip the basic S1.

Other Features

All the printers in the Ender 3 S1 series receive a filament run-out sensor which was present solely on the Ender 3 Max in the previous generation. It's a nice feature to have on any printer and reduces the chances of print failures.

The Ender 3 S1 Pro stands out in the lineup with its integrated LED light bar and a platform handle on the print bed. Furthermore, all the printers in the S1 lineup are compatible with external accessories such as Creality's WiFi box and laser modules. These accessories extend the printers' functionality and help you execute additional tasks on the machines.

All the S1 printers retain the XY axis belt tensioners and the toolbox from the Ender 3 V2 and utilize a 32-bit motherboard with silent stepper drivers. These are great features from the previous generations, and it's nice to see them in Creality's premium S1 series too.

Creality has also improved the assembly process considerably, and almost 95% of the printer comes pre-assembled. It's a neat improvement and saves substantial assembly time. Easier assembly is also great for beginners and makes the printers more user-friendly.

Ender 3 Neo Series

The Neo series 3D printers are the latest in the Ender 3 lineup, with all three printers being released in August 2022. These Neo printers are a mix between the original Ender 3s and the Ender 3 S1 3D printers and are positioned as a budget variant of the premium S1 printer.

Like the previous generation of S1 printers, you get three 3D printers in the Neo series too. The Ender 3 Neo is the baseline version, with the Neo 2 being the top-end printer and the Neo Max being the large volume 3D printer. All the printers are different in their designs and features and lack the uniformity of the S1 series.

Regarding the spec sheet, most features are similar to the Ender 3 series, with some elements from the Ender 3 S1. Overall, these Ender 3 Neo printers are a decent buy if you're looking for an upgraded Ender 3 printer but do not want to spend too much for the premium features of the S1 series.

Let's understand the differences in features between these Neo printers.

Comparison Sheet

| Features | Ender 3 Neo | Ender 3 Neo V2 | Ender 3 Neo Max |

|---|---|---|---|

| Build Volume | 220 x 220 x 250 mm | 220 x 220 x 250 mm | 300 x 300 x 320 mm |

| Release Year | 2022 | 2022 | 2022 |

| Machine Dimensions | 440 x 440 x 465 mm | 438 x 424 x 472 mm | 516 x 582 x 590 mm |

| Extruder drive | Bowden (Metal) | Bowden (Metal) | Bowden (Metal) |

| Max hot end Temperature | 260 °C | 260 °C | 260 °C |

| Max print bed temperature | 100 °C | 100 °C | 100 °C |

| Print surface | Carborundum glass | PC spring steel magnetic plate | Carborundum glass |

| Bed Leveling | CR-Touch auto-leveling | CR-Touch auto-leveling | CR-Touch auto-leveling |

| User Interface | Rotary Knob LCD | Color HD screen with Rotary knob | Color HD screen with Rotary knob |

| Dual Z-axis | No | No | Yes |

| Belt Tensioners | No | Yes | Yes |

| Filament sensor | No | Yes | No |

| Price | $219.00 | $299.00 | $389.00 |

Build Volume

The Ender 3 Neo and the Neo V2 both feature a modest 220 x 220 x 250 mm build volume, similar to the original Ender 3s. Creality has reduced the build height from 270 mm in the S1 printers to 250 mm in the Neo series. It is a minor reduction and doesn't affect the printers' utility or printing performance.

Like the previous big-sized printers, the Ender 3 Neo Max receives a large build volume of 300 x 300 x 320 mm, which is adequate for printing most 3D printing stuff. It's a reasonably large print area, and the Neo Max presents a great alternative to the CR-10 3D printers.

Auto-Bed Leveling

Creality has retained the automatic leveling feature in the Ender 3 Neo printer. All the machines feature a CR-Touch leveling probe and offer a 16-25 point auto-leveling feature. This feature is excellent for print adhesion and comes in handy on the large printing area of the Ender 3 Neo Max printer.

Extruder-Hot End

The Ender 3 Neo series skips on all-metal hot ends, and all three printers get a PTFE-lined hot end with a Bowden extruder. Considering its price and purpose, it's adequate for printing with essential filaments such as PLA, ABS, and PETG.

However, Creality has improved the heat sink on the hot end. According to the company, the new fin design helps dissipate the heat faster, leading to better cooling performance and helps to maintain a stable printing temperature.

The Bowden extruder, too, features a full-metal body and adds to the durability of the 3D printer. This metal assembly reduces print failures and ensures smooth and even pressure on the filament.

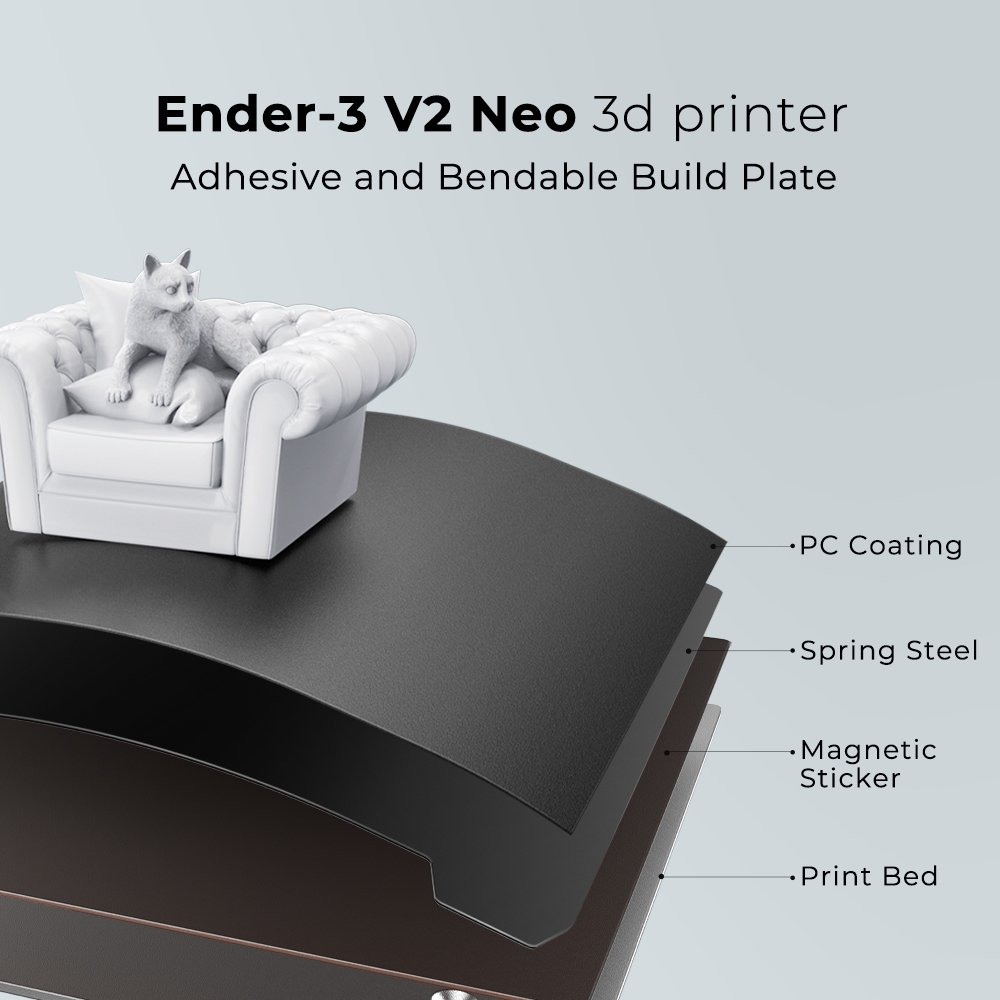

Print Bed

Creality went with carborundum glass print beds on the Ender 3 Neo and the Neo Max. It's an excellent printing surface and is great for heat distribution and print adhesion. But, you might have issues with print removal of specific materials and need additional tools.

The Ender 3 Neo V2 gets a PC-coated spring steel magnetic print bed, which is far better than a glass surface. It's easy to use, offers excellent print adhesion and the prints come off quickly with a slight flex. However, considering that the standard Neo 3D printer has the same build area, it's compatible with the PC print bed.

User Interface

Creality brought back the old and dated TFT screen on the Ender 3 Neo 3D printer. It's probably the same as the one used on the 4-year-old Ender 3 and does not offer an excellent look to the printer. The user interface is old, and you're limited in features and ease of use.

The Ender 3 Neo V2 and the Neo Max screens are full-color screens with knob control. They're easier to use, have a clean UI, and are much better than that on the standard Neo. Additionally, the Neo V2's screen lets you preview your model, which is great for visualizing your prints before you begin them.

Other Features

The Ender 3 Neo V2 has the same design as the S1 printers, lacking the Neo and the Neo Max. The XY axis belt tensioners, filament knob, and toolbox in the Neo V2 are extremely handy for quick maintenance and storage.

The Ender 3 Neo Max gets the dual-z axis design due to its large printing volume. It helps with print quality for tall prints and reduces the bending of the printing arm. The Neo Max also features a filament run-out sensor which is excellent for large 3D prints and will significantly reduce print failures due to a break in the filament.

Assembly-wise, the Neo V2 and the Neo Max are the easiest and quickest to put together. These printers come primarily pre-assembled, and you can start printing on them within an hour. In contrast, the Ender 3 Neo requires some assembly, and even though it's easy, it is not as quick as the other two printers.

These were all the differences between every Ender 3 3D printer from three different series. In summary, the original Ender 3 printers are extremely basic and offer great value for their price. These printers will be an excellent choice for beginners, hobbyists, and educational institutes looking for their first 3D printer on a budget.

The Ender 3 S1 series is suited for more high-end and professional use and comes with a premium set of features designed to deliver a rich 3D printing experience. The Ender 3 S1 Pro is the sole printer to feature an all-metal hot end in the Ender 3 series and will be excellent for demanding materials.

At last, the Ender 3 Neo printers fall between these two series and represent an excellent alternative for budget users. You receive all the essential features, such as auto-bed leveling, color screen, and metal extruders, which are adequate for delivering a decent printing experience.

However, none of these 3D printers feature remote control and monitoring functionalities. And while you can install a WiFi box in the S1 series, the remote experience is not comparable to other methods such as Octoprint or Klipper.

Amongst the two, Octoprint is a more popular and widely used remote control host software for 3D printers, yet, it's still limited to controlling your printer over the same wireless network.

This is where the Obico tool steps in.

Obico for Octoprint

Obico is a remote monitoring and control solution for 3D printers. It's available as an Octoprint plug-in and is free to download and open-source.

Essentially, Obico lets you access your 3D printer from anywhere and control it from any device of your choice. You can attach a camera to the Raspberry Pi and view your printer's live feed on your smartphone or tablet from anywhere in the world.

It also features AI detection capabilities that recognize any print failures in an ongoing print. You can get instant notification about the print's status and choose to cancel the print in case of failure. This feature helps you to save lots of filament material, printing time, and costs.

You can sign up for free on the Obico website and refer to a detailed guide to set up Obico for Octoprint. The process is straightforward, and once everything is set up, you can start to experience the true meaning of remote 3D printing.

If you have issues getting Obico installed for your 3D printer, check out the complete setup guide or join the Obico discord server to get help.

Let us know your experience of using the Klipper for Ender 3. If you find Obico useful, please give us a star on GitHub, or leave us a review on our mobile app in the iOS App Store or Google Play Store!