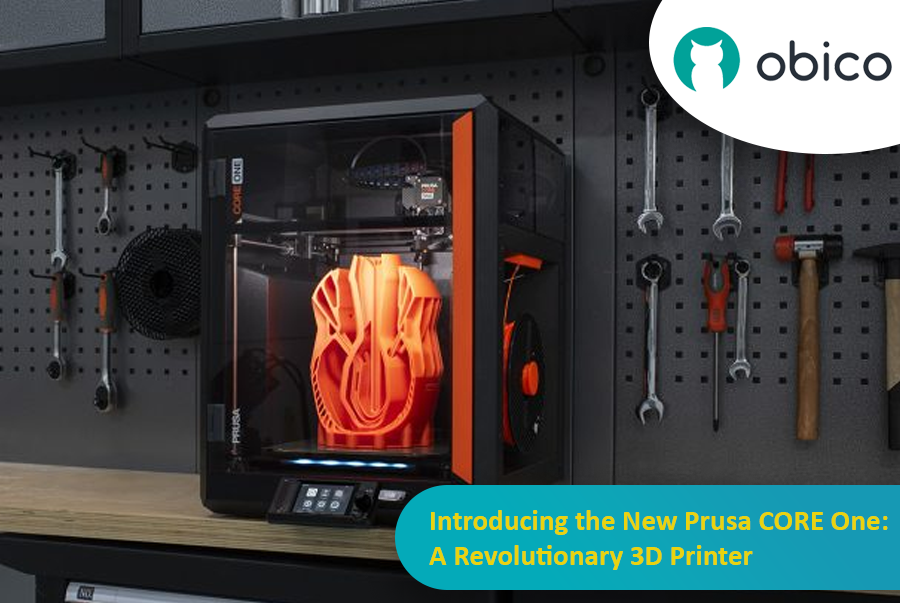

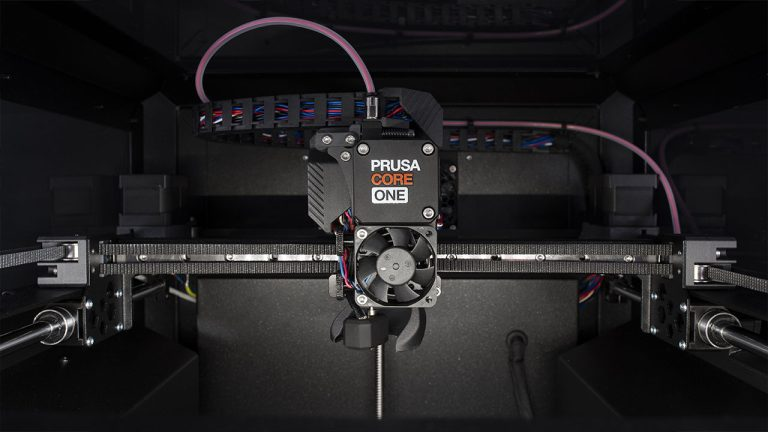

Introducing the New Prusa CORE One: A Revolutionary 3D Printer

The 3D printing world has just got a new game changer: the Prusa Core One. This is not just a new printer; it’s a leap forward in design, functionality, and performance. The new CORE One printer offers a CoreXY design, active chamber temperature control, and a host of user-focused innovations. It combines speed, precision, and versatility in a sleek, compact package.

Whether you are a hobbyist looking to expand your creative possibilities, a professional engineer in need of reliable prototypes, or a teacher exploring 3D printing, the Prusa CORE One has something for everyone.

Let’s take a closer look together at what makes this new printer a true standout.

The Core of the CORE One: What’s New?

Prusa Research has been in the 3D printing business for years. We have reliable and innovative machines like the Original Prusa MK series and the XL. But the CORE One brings something entirely new:

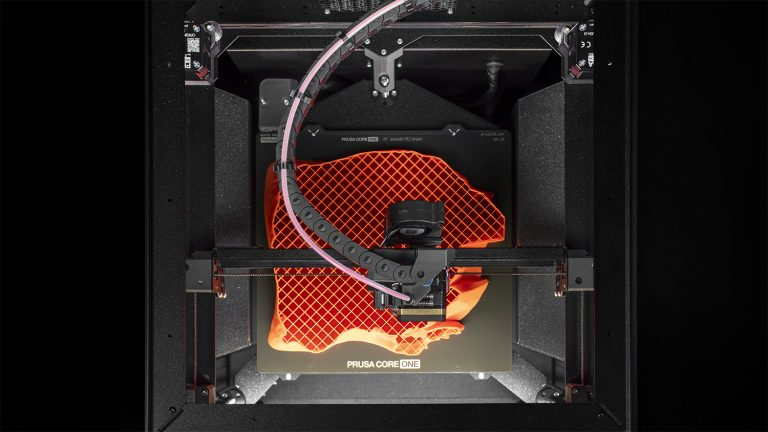

The CORE One is powered by CoreXY mechanics, a system that changes the way 3D printers work. Unlike traditional Cartesian printers, where each axis is driven by one motor, CoreXY uses belts and pulleys to move the printhead along the X and Y axes, while the bed moves in the Z axis. This design minimizes moving mass, reduces vibrations, and ensures consistent print quality.

Source: prusa3d.com

This motion system is fast and precise. By minimizing vibrations, the CORE One produces clean surfaces, sharp details, and smooth edges even at high speeds. It’s a system designed for efficiency, so you can create detailed prototypes, artistic models, or functional parts faster than ever before without compromising on quality.

Compact Design with Exceptional Capability

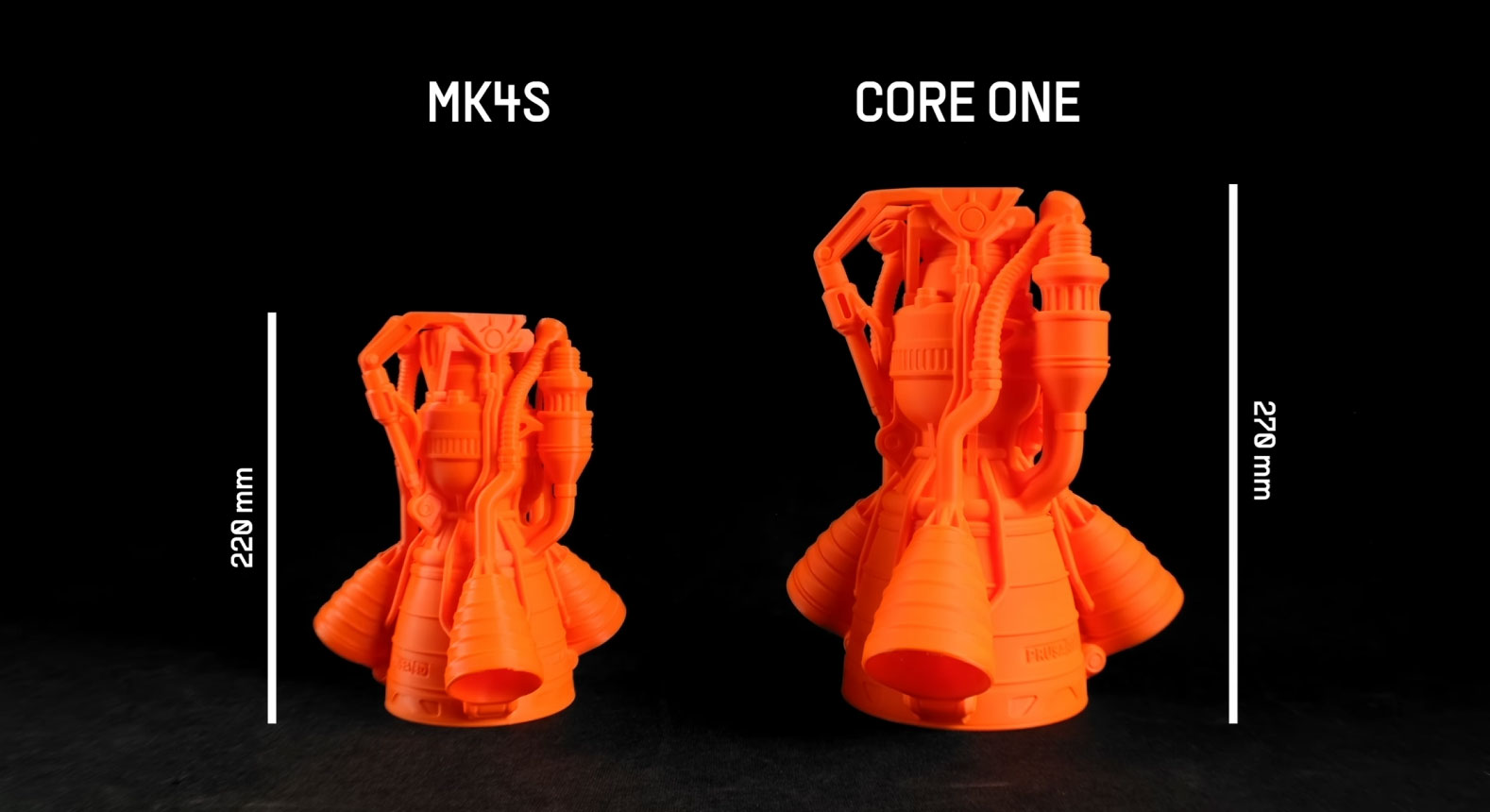

One of the most impressive features of the CORE One is its compactness. At 415×444×555 mm in size, it takes up much less space than traditional printers with enclosures, making it perfect for those with limited space. Despite its small footprint, it has a build volume of 250×220×270 mm, so you can print bigger and more complex models than ever before.

Source: prusa3d.com

This compactness and capability make the CORE One perfect for home workspaces, classrooms, and professional studios. Whether you’re printing intricate decorative pieces or big functional parts, the CORE One gives you the flexibility to bring your ideas to life without taking over your workspace.

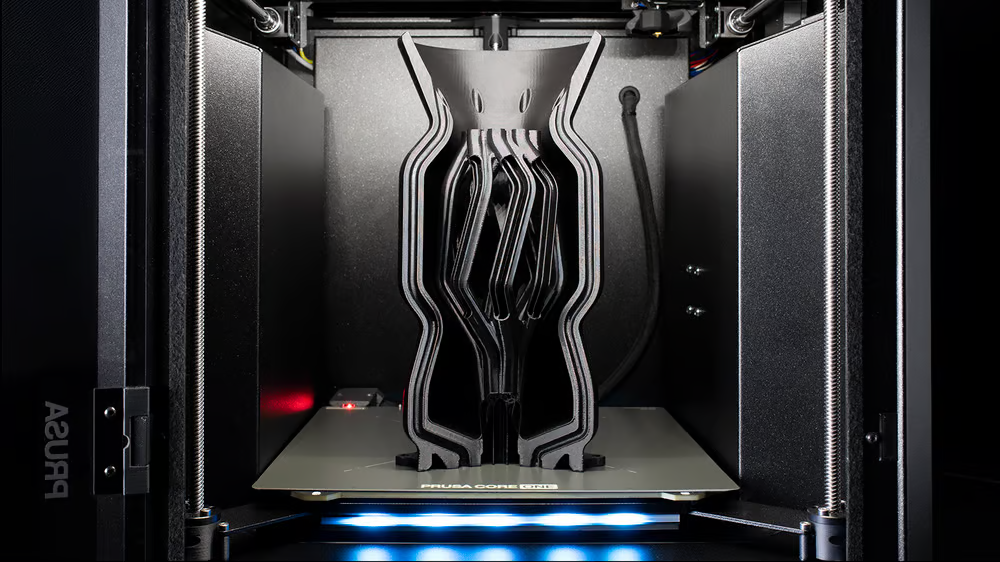

A Heated Chamber for Every Material

The CORE One’s fully enclosed, temperature-controlled chamber is a game changer. Traditionally, enclosed chambers were reserved for high-end industrial machines, but the CORE One brings this feature to a wider audience. With the ability to heat the chamber to 55°C, it creates the perfect environment for challenging materials like ASA, ABS, nylon, and polycarbonate. These materials are known for their strength and durability but often warp or crack without proper temperature control. The CORE One eliminates these issues so you can print with confidence.

Source: prusa3d.com

What really sets this chamber apart is its flexibility. Unlike many printers that struggle with temperature-sensitive materials like PLA and PETG in enclosed spaces, the CORE One has an active ventilation system, so you can print with beginner-friendly materials with the door closed without sacrificing quality or convenience. From simple projects to industrial-grade parts, the CORE One can handle it all.

Engineered to Last: The All-Steel Exoskeleton

Durability and longevity were the guiding principles behind the CORE One’s design. Its innovative all-steel exoskeleton takes inspiration from structures in nature, such as the outer shells of crustaceans and insects, where the external skin doubles as both protection and structural support. Similarly, the CORE One’s exoskeleton serves as the printer’s frame and its outer enclosure, combining strength and functionality in a single design.

Source: prusa3d.com

This approach makes the printer more robust and efficient to manufacture. Unlike other designs that have welded cubes with enclosures or open-frame printers inside a box, the CORE One has all these elements in one. This minimizes vibrations during printing, stabilizes the machine for consistent results, and creates a sleek, compact form factor.

The modular exoskeleton design makes maintenance easy and cost-effective. All components can be disassembled and replaced with a screwdriver, extending the printer’s lifespan and making it a future-proof investment. This thoughtful design allows the CORE One to adapt to upgrades and evolving user needs, making it a reliable long-term solution for 3D printing.

Precision and Performance with the Nextruder

At the heart of the Core One’s print quality is its Nextruder. The upgraded Nextruder is a direct-drive extruder with the latest technology, including a Loadcell sensor that ensures perfect first-layer calibration on every print. Unlike traditional sensors, the loadcell measures pressure, so it’s very reliable on different surfaces and materials.

Source: prusa3d.com

The Nextruder’s 360° cooling system improves overhang performance, reduces the need for supports, and saves time and material. The high-flow nozzle included as standard allows for faster printing without sacrificing quality. The result is a printer that’s fast, precise, and efficient to produce perfect models, whether you’re printing intricate designs or robust functional parts.

Seamless Setup and User Experience

The Core One is designed for users of all levels. Setting it up is easy—unbox the printer, do a quick calibration, and start printing. Even beginners can be up and running in 10 minutes. It is one of the most user-friendly printers on the market.

Automatic filament detection and door safety sensors make life even smarter. The printer pauses if the filament runs out, so you can replace it without losing your work. These nice touches make the CORE One a hassle-free machine so you can focus on your projects, not troubleshooting.

Versatility for Every User

The versatility of the CORE One is one of its greatest strengths. For hobbyists, it offers access to nearly a million free 3D models on Printables.com, opening up endless creative possibilities. From custom tools to cosplay props and home decor, the CORE One lets you bring your ideas to life with exceptional quality.

Professionals will appreciate the CORE One’s ability to handle advanced materials and produce prototypes with precise dimensional accuracy. Its speed and reliability make it an invaluable tool for engineers, designers, and manufacturers alike.

Educators can use the CORE One to inspire students with hands-on learning experiences. Its enclosed design ensures safety, while its intuitive controls make it easy for young learners to explore the world of 3D printing.

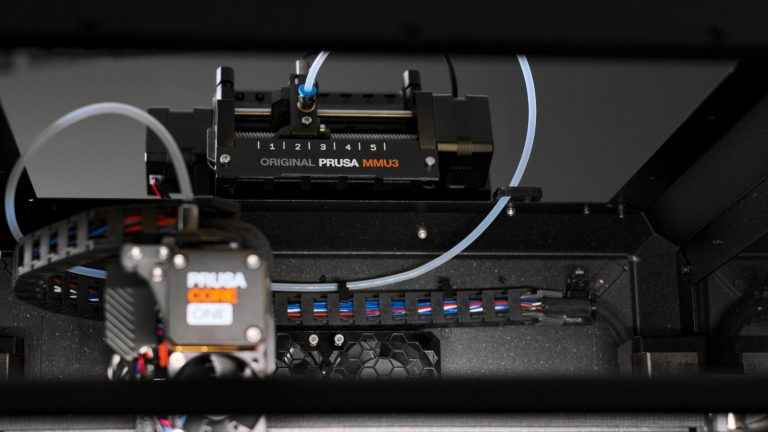

Room for Growth with Accessories and Add-Ons

The CORE One is more than just a standalone printer; it’s a platform designed for growth and customization. Prusa offers a range of optional accessories that allow you to tailor the printer to your needs.

Source: prusa3d.com

The Multi-Material Upgrade (MMU3) enables printing with up to five colors or materials at once, while an optional in-chamber camera lets you monitor prints remotely.

An advanced filtration system is also available to reduce fumes and particles, making the printer suitable for more demanding materials and safer for enclosed spaces. Additionally, the GPIO hackerboard provides opportunities for customization, allowing users to add external controls and expand functionality.

These accessories will keep the CORE One up to date as your needs change, so it’s a future-proof investment.

The Value of the CORE One

The CORE One is a great value for the features and build quality. The assembled version is priced at $1,199, while the kit version—perfect for those who enjoy hands-on assembly—will be available in April 2025 for $949. Shipping for the assembled version begins in January 2025, ensuring you won’t have to wait long to start exploring its capabilities.

So, Why Choose the Prusa CORE One?

Pros

- Exceptional build quality with a durable steel exoskeleton

- Versatile material compatibility, including advanced filaments

- Active chamber temperature control for warp-free printing

- Speedy and precise CoreXY mechanics

- Easy setup and intuitive controls

- Expandable with a range of add-ons

- Strong support and long-term upgradability

Cons

- Higher upfront cost compared to entry-level printers

- Some accessories (e.g., filtration system, camera) sold separately

FAQs

1. What makes the Prusa CORE One different from the MK4S and XL?

The Prusa CORE One has CoreXY mechanics for faster and more precise printing, a fully enclosed and actively temperature-controlled chamber. It can print a wide range of materials, including ABS and nylon, with minimal warping. Compared to MK4S, it has a larger print volume (250×220×270 mm) and a smaller footprint when enclosed. Compared to XL, it’s more compact and designed for single-nozzle printing, making it suitable for a wider range of users.

2. What materials can the CORE One print?

The CORE One is compatible with:

- Basic materials: PLA, PETG

- Advanced materials: ABS, ASA, PC, Nylon (PA)

- Flexible materials: TPU

- Specialty materials: Carbon-fiber-reinforced filaments, PVA (water-soluble)

Its actively heated chamber ensures stability for advanced materials, while the ventilation system optimizes conditions for PLA and PETG, even with the door closed.

3. How easy is it to set up and use the CORE One?

The CORE One is designed to be simple and user-friendly. Setup takes less than 10 minutes; one-time calibration, and you’re good to go. The printer comes with a 3.5-inch color touchscreen, making navigation and adjustments intuitive. A loadcell sensor is also included to ensure perfect first layers automatically, so you can focus on your projects instead of troubleshooting.

4. Can I use the CORE One without connecting it to the internet?

Yes! The CORE One has a fully offline mode. You can transfer files via USB and update firmware without internet. This is great for users in high-security environments or those who don’t want to connect their devices to the cloud.

5. What optional add-ons are available for the CORE One?

The CORE One can be expanded with:

- Buddy3D Camera: For remote print monitoring via the Prusa Connect app.

- Advanced Filtration System: Reduces fumes and particles when printing materials like ASA or ABS.

- MMU3 Multi-Material Unit: Enables printing with up to five colors or materials simultaneously.

- GPIO Hackerboard: Allows advanced users to control external devices like LED lights or cameras using G-code.

These add-ons make the CORE One more versatile and user-friendly for hobbyists and professionals.

6. How does the CORE One handle maintenance?

The CORE One is designed to be long-lasting. The modular design means most parts can be replaced with screwdrivers, and spare parts will be available for years. Prusa’s durable materials, like carbon-fiber-reinforced polycarbonate, will withstand heavy use. The printer also has sensors for fan, filament, and door status to reduce unexpected issues.

7. Is the CORE One suitable for beginners?

Yes! Despite being advanced, the CORE One is beginner-friendly. Automatic calibration, preloaded material profiles, and an intuitive UI make it ready to print straight out of the box. Plus, Prusa Academy courses and tutorials will help you learn the basics of 3D printing in no time.

8. How does the CORE One compare to other CoreXY printers on the market?

Many CoreXY printers focus on speed but compromise on usability or print quality. The CORE One balances the speed and precision of CoreXY mechanics with Prusa’s focus on reliability, quality, and user experience. The active heated chamber, robust exoskeleton, and advanced sensors make it a unique offering in its class.

9. What is the price and availability of the CORE One?

The CORE One is priced at:

- $1,199 (assembled)

- $949 (kit)

Shipping starts in January 2025, and the upgrade kit for MK4S owners is expected in March 2025. Assembly kits will be available in April 2025 for those who want to build their printer themselves.

10. What support is available for CORE One users?

Prusa offers 24/7 support via live chat and email in multiple languages. Plus, the Prusa community is very active with forums, tutorials, and user-generated tips. Whether you’re troubleshooting or looking for inspiration, help is always available.

11. Can the CORE One be used in professional environments or print farms?

Yes, the CORE One is designed for individual users and high-volume operations. Its small footprint, robust construction, and ability to print advanced materials make it perfect for print farms, workshops, and design studios. Air extraction compatibility and low maintenance requirements make it even more suitable for professional use.

Final Thoughts

The Prusa Core One isn’t just a 3D printer; it’s a complete solution for creators, professionals, and educators. Speed, precision, and material versatility make it a tool for any application. Whether you’re printing prototypes, creating art, or running a print farm, the CORE One will deliver consistent, high-quality results.

With its durable construction, thoughtful design, and focus on user experience, the CORE One represents a new era of 3D printing. If you’re looking for a reliable, future-proof machine that pushes the boundaries of what’s possible, the CORE One is worth every penny.

If you’re interested in learning more or purchasing the Prusa CORE One, you can visit the official product page here: Prusa CORE One.

Happy printing! 😉