Try JusPrin, the first GenAI 3D printing tool built on OrcaSlicer.

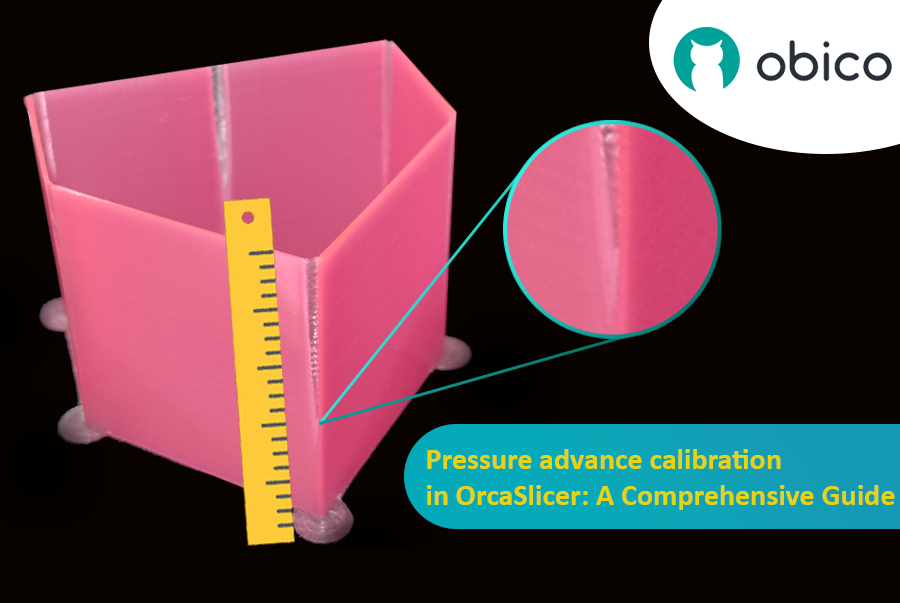

Wyobraź sobie, że rysujesz długopisem, który czasami rozlewa zbyt dużo tuszu, a czasami prawie wcale. W druku 3D coś podobnego może się zdarzyć, gdy drukarka porusza się szybko i zmienia swoją prędkość – może to zepsuć ilość wylewanego plastiku.

Ale dlaczego Twoja drukarka czasami psuje ilość plastiku, którą wypuszcza?

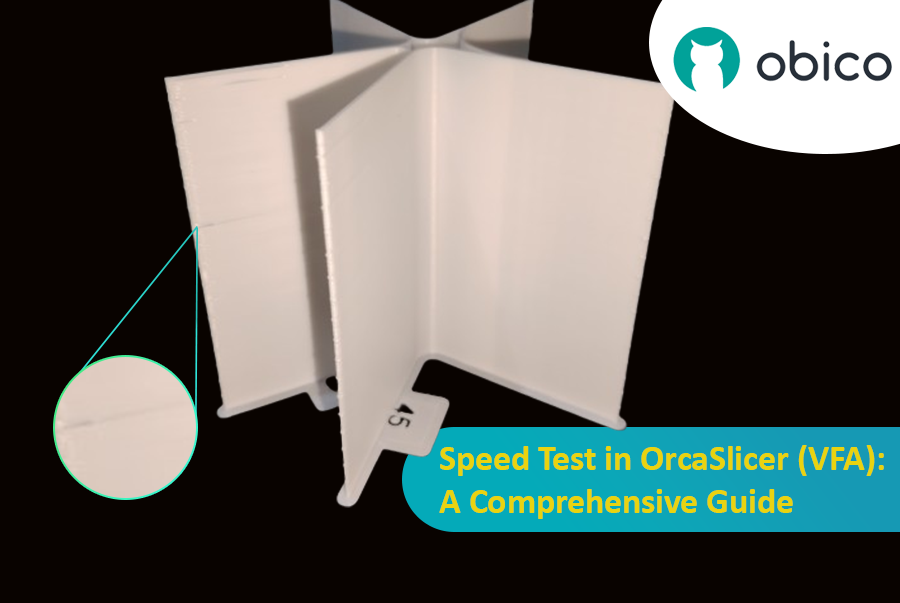

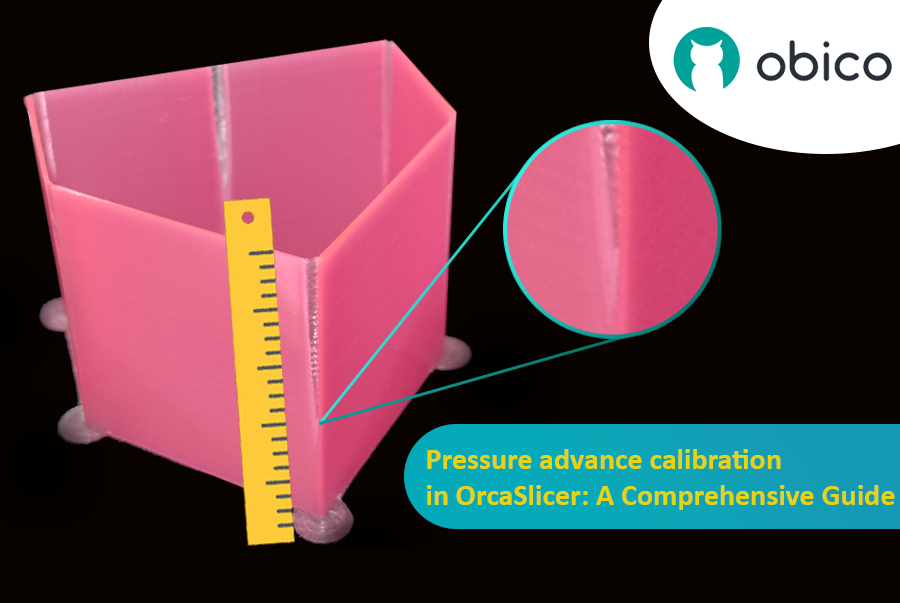

W drukarce 3D filament wychodzi w zależności od tego, jakie ciśnienie panuje w dyszy. To jak wąż ogrodowy; potrzebujesz odpowiedniego ciśnienia wody, zanim woda wytryśnie. Kiedy drukarka przyspiesza lub zwalnia, np. podczas pokonywania zakrętów, potrzeba trochę czasu, aby ciśnienie dyszy nadrobiło zaległości. Jeśli drukarka porusza się zbyt szybko, zbyt wcześnie, nie wychodzi wystarczająco dużo filamentu. A jeśli zwalnia zbyt szybko, wychodzi za dużo filamentu. Może to sprawić, że rogi wydruku będą wyglądać trochę niechlujnie, ponieważ drukarka nie dostosowała przepływu filamentu dokładnie do zmian prędkości.

I tutaj wkracza Pressure Advance. To inteligentna funkcja, która kompensuje te zmiany, zapewniając, że odpowiednia ilość filamentu jest wytłaczana, gdy drukarka przyspiesza lub zwalnia. Dzięki Pressure Advance drukarka lepiej radzi sobie ze zmianami prędkości, co prowadzi do gładszych, ostrzejszych wydruków, szczególnie w trudnych narożnikach.